LockboxLockbox Design and BenefitLockbox Design and Benefi

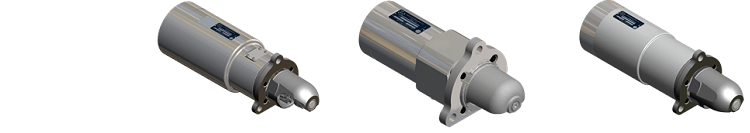

Utilizing a KTI patented ASME approved closing arrangement, Lockbox accumulators may be disassembled within minutes and without the need of specialized tooling, allowing end users to perform efficient field maintenance. Traditionally, accumulators have relied heavily on threaded arrangements which are susceptible to galling and corrosion. Incorporating proper engineering practices to mitigate these issues increases cost, lead time, and complexity, reducing the availability of replacement parts. With Lockbox these issues are eliminated, allowing rapid maintenance to be performed by anyone, anywhere.

Lockbox allows end users the ability to easily disassemble a unit much quicker than a standard accumulator. This would be especially useful in offshore oil and gas applications where accumulators are consistently scheduled for maintenance. Scheduled maintenance costs oil drillers millions of dollars in downtime so the ability to disassemble on site would drastically cut down lead time during disassembly and inspection. Additionally, if a driller would rather send the units back to shore, KTI can easily disassemble and inspect the units in a matter of days rather than weeks. The other main application for Lockbox is testing settings. Certain testing scenarios may lead to consistent maintenance on the accumulator so easy disassembly cuts down on labor and other inspection costs. In general, the main applications for Lockbox accumulators revolve around scheduled maintenance or inspection. If a sizable accumulator needs to be taken apart consistently, then Lockbox is the way to go.

Translate

Translate